Looking for a solution to your test project?

As your solution partner we analyze the specification of your test object, design the project and implement it – up to complete integration into your production process.

- Analyzing and planning the test

- Conception of test hardware

- Creating the test programs

- Integration into production process

- Training und support

Turn-key solutions

The end-of-line test is the last step in the production chain. The findings of the EOL test can be used to improve the process quality in upstream production steps, if appropriate data records and data analyzes are carried out. A meaningful functional test, therefore, apart from the good/bad selection mainly makes an evaluation of statistical data and trends.

In our solutions we fundamentally consider

- Accuracy of measurements

- Stability of measurements

- Speed optimization for highest throughput

We create high-quality solutions for our customers based on our own hardware concepts. We use suitable and common instruments on the market and integrate them into our solutions. Standard interfaces such as GPIB, PXI, LXI, USB, RS232 but also special interfaces are used. In our Tecap Software Platform, all devices are integrated and can be used on a high-level via the user interface.

Automotive

Test of a Keyless Entry DCS ECU

Short description

A global supplier for the automotive industry needs to test a door controller with keyless entry functionality.

Kommunikation Keyless Entry

The ECU sends on 433 MHz or 426 MHz. Important while analyzing the signal is the frequency modulation gfsk and encryption. Additionally the transmitted message is manchester encoded. The received and transmitted signals are checked.

The antenna in the RF chamber is calibrated by a golden device.

Application adapter

The DUT is connected with the test rack by a hardware interface. The test rack has 18 slots; six are used for the application. The application is controled by the test rack bus and the DUT is connected to the internal tester instruments. Additionally the test rack contains signal conditioning cards between the PXI instrumentation and the DUT.

Hardware

Platform is MTQ Hilerion

PXI Instrumentation

- Pickering Matrix

- NI – DMM

- NI Vectoranalyzer

- NI Vector Generator

- MTQ Power Distribution

- CM50 Floating Range Current Measurement Unit

- Lambda Genesys Power Source

Application

- Communication between the simulated key and the ECU

- extensive CAN bus communication

- a lot of high current channels for mirrors and window lifter motors

- testprogram life cycle from the first sample to the final tested repetition part

Documentation

- System description

- User manual

- Risk analysis

- CE-decleration

- RF-chamber measurement protocoll

- Electric diagrams

RF chamber internal view The chamber is SPC controlled. DSUB filter connectors to suppress DUT or signal generator high frequency radiation.

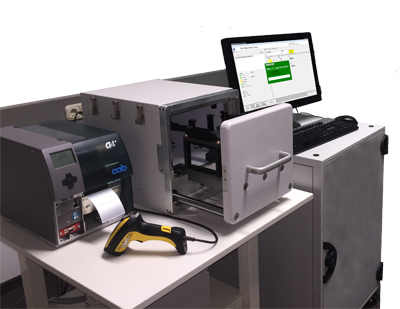

PXI Chassis with measurement equipment and application rack

ECU for keyless entry and another different ECU – application on one platform

Applications based on the test extension rack TEX09 normally don't need too many slots. Therefore there are many slots for further applications available. For our automotive customer we could not only plug in the application for keyless entry but also place another application cost effectively into the same test rack.

The application is without additional changeover effort selectable by loading the appropriate test software package.

Cabinet view to application connectors. You see the cable for the DCS application and the connectors for the duplex adapter.

Duplex adapter with asynchronous handling

Industrial Applications

Semi automated test of power plant control room systems

MTQ Project

- Concept definition

- Administration

- Wiring and assembly

- Documentation

Tecap Project Facts

- partial automated test of 80000 signals for 200 cabinets

- Parametric visualising of so called „Typicals“ = standardized measurement tools for Analog-in or analog out, binary inputs and – outputs, simulation of motors and impulsions

- Mass signal generation

Technology

- System- platform: PXI/LXI Switching System

- Pickering Matrix 3072 x 64 (24 Matrices á 128 x 4) extended by Multiplexer 5 x 32

- LXI – Backend Matrix 64x48

- Signal path interconnection Wire Wrap wiring of 24 Matrices (24x128) to 32 connectors (32x96)

Test cabinet front view

Semiconductor

Sensor test on wafer

MTQ Project

The technological challenge has been the precise measurement of resister networks. The expected quality of the measurement result didn't allow to realize result calculation out of different values. Therefore MTQ developed a guarding concept for the 7 1/2 Digit DMM. That enabled these high accuracy measurements. The guard amplifier is connected via the system matrix to each of the relevant nodes.

- Concept definition

- System development

- Wiring and mounting of matrices, measurement equipment and porbe card

- Test development

- Factory integration

- Documentation

Technology

- 19" cabinet with power management

- PXI matrix system

- DMM 7 1/2 digit Keysight 34470A

- Präzisions MTQ guard amplifier isolating R-Bridges for a measurement precision of 0.001%

- VXI 4Q U/I Source PX773x

- EG Waferprober

Tecap Project Facts

- Tecap Test & Measurement Software

- Measurement of the sensors with Autorouting Tecap Switching

- Control of EG Waferprober and proccess management

- Datalogging and WaferMapping

- Connection to customer database

Test system with waferprober EG

Further Applications

EMS / Automotive

- Platform: Customer system

- System integration and test program conversion

- Standardized replacement of old solutions

- Increase of throughput saves test time by 56%

Mobile energy solutions

- Intelligent batteries and charger

- System platform: PXI-Rack, Pickering, NI, a.s.o.

- Tecap performs as the general solution from ground up

- Communication with DUT

Industrial electronic motor control

- System platform: MTQ customer project based on TEX09 with PCI/IEEE measurement equipment

- CANopen communication

- On Board Programming